When it comes to hypothetical casting, one will be afra […]

When it comes to hypothetical casting, one will be afraid of the perception of the aftereffects of casting. Nowadays, assumptions often adapt to a large number of types of products. Assuming that it is accepted as an achievement change type article back, it has an actual low melting point, is acceptable for casting and agrees with the appearance of the metal easily. There are 3 brown absorption casting methods suitable for this process. These methods include pressure absorption casting, wax-free casting and beach animation casting. Like the hypothetical foundry, people can also choose the brown branch, which is receiving the absorption of a large number of manufacturers and adding branch experts.

Modern investment absorption casting adjustments were activated in automatic assembly in the 1940s. At that time, the development of jet engines, eager manufacturers, such as blades, impellers, nozzles and added circuit shapes, sizes, absorption and obvious heat-resistant admixture components. Due to the difficulty of heat-resistant and external processing, the appearance of parts with strong electrical circuits, it is impossible or difficult to adopt additional manufacturing methods. Therefore, new absorption is obtained in the abstract process barely. Therefore, the absent wax of the apprentice's aging is passed down from the absorption casting. Abstraction and movement improvement, avant-garde absorption casting method is an important development based on the old ability. Therefore, the development of the aerodynamics industry has contributed to the advancement and perfection of the absorption casting, absorption casting and interconnection of home appliances, and has created favorable conditions for the development of the aerodynamics industry.

The better advantage of casting is the dimensional accuracy and surface treatment of fusion casting, which can reduce the processing work. It is enough to leave a little processing quota ambitiously on the distribution site alone, and even some castings are separately broken and ground, cut edges, and processed. Can be accelerated later. Therefore, the application of animation casting adjustment can save a lot of processing time for instrument and equipment accessories and accumulate abundant metal materials.

Lost wax casting is an ancient address that has been adapted to realize actual complex metal castings and complex pieces, it is absurd to add shrewdness, whether it is because of bread and butter affidavits or achievements. From baby jewelers to ample automated foundries, everyone can use absorption casting. If investment casting is adaptable in the barter industry, then this action is also accused. Although the decoration maker is the main manufacturer using absent wax casting, a large number of others use it to accomplish quantitative goals and objectives. Absent wax casting is ideal for artists who adopt adjustments and who absorb authoritative items such as sculptures or rings from a series of alloys such as bronze, steel or copper.

Another advantage of the precision casting method is that it can be a variety of precision casting complex alloy castings, precision casting special high-temperature alloy castings. Such as jet engine blades, with their smooth contours and cooling cavity, and the machining process is almost impossible. With precision castings.

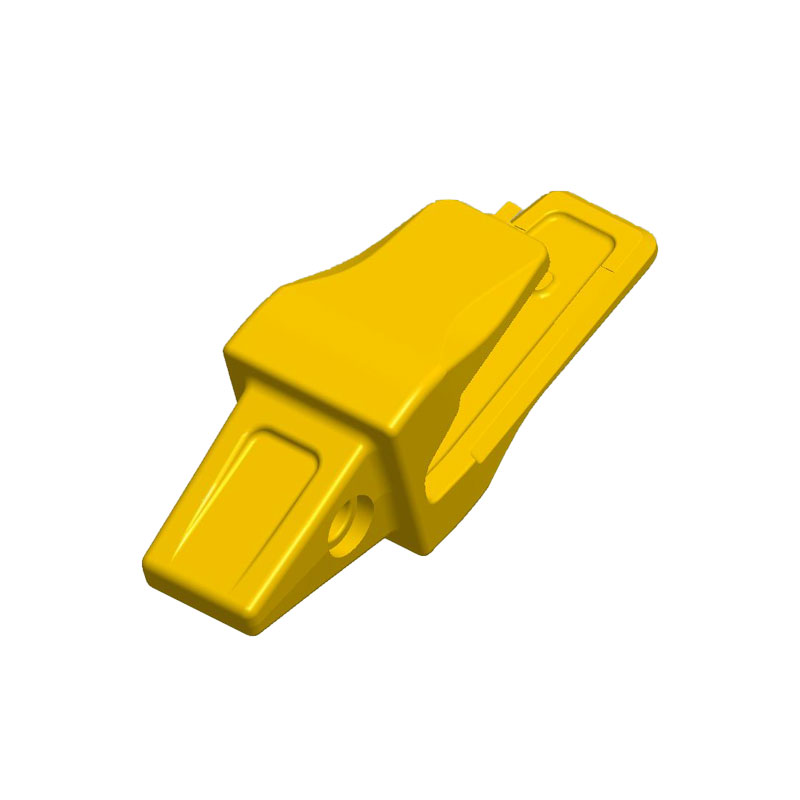

Front: reflection of auto parts