Carbon and alloy steel casting parts play a crucial rol […]

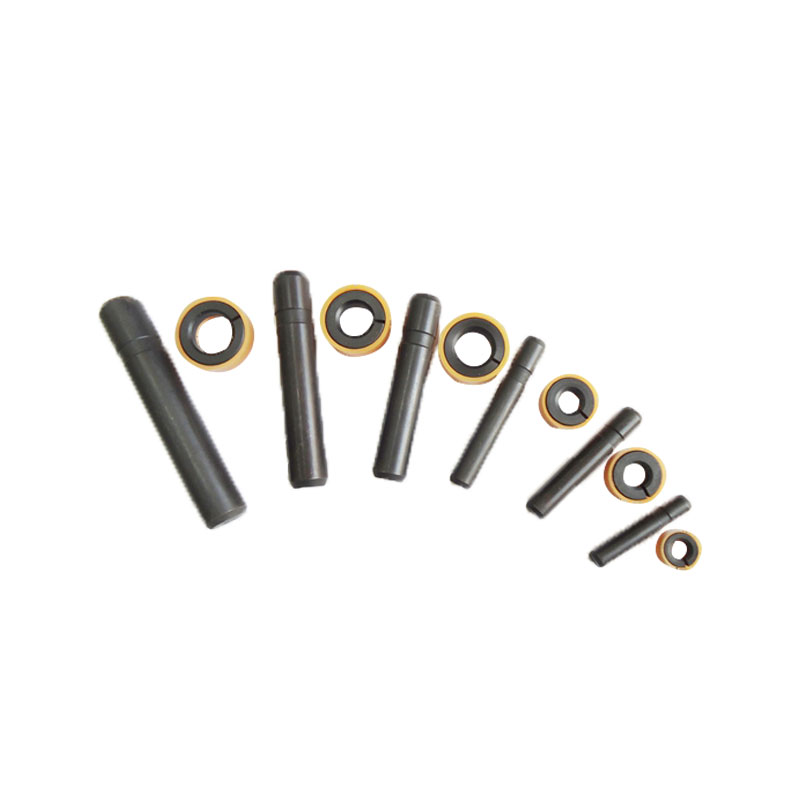

Carbon and alloy steel casting parts play a crucial role in various industries, ranging from automotive to heavy machinery. These parts are produced through the casting process, which involves melting the steel and then pouring it into a mold to create the desired shape.

Carbon steel, known for its high strength and ductility, is a common choice for casting parts that require both durability and formability. Its composition, primarily consisting of iron and carbon, allows it to be easily molded into complex shapes while maintaining excellent mechanical properties.

On the other hand, alloy steel casting parts offer enhanced performance due to the addition of alloying elements such as chromium, nickel, and molybdenum. These elements improve the steel's corrosion resistance, wear resistance, and high-temperature performance, making alloy steel casting parts suitable for demanding applications.

The casting process for carbon and alloy steel parts begins with the preparation of the mold, which is typically made from sand or metal. The molten steel is then poured into the mold and allowed to cool and solidify. Once the part has cooled, it is removed from the mold and may undergo further processing, such as machining or finishing, to meet specific requirements.

The advantages of using carbon and alloy steel casting parts are numerous. Firstly, casting allows for the production of complex shapes that would be difficult or impossible to achieve through other manufacturing methods. Secondly, casting can be a cost-effective way to produce large quantities of parts with consistent quality. Additionally, the mechanical properties of carbon and alloy steel make these casting parts suitable for use in high-stress environments.

However, it's worth noting that the casting process can introduce certain challenges, such as porosity, shrinkage, and deformation. To mitigate these issues, manufacturers often employ advanced techniques and strict quality control measures.

In conclusion, carbon and alloy steel casting parts are an essential component in various industrial applications. Their excellent mechanical properties, combined with the flexibility of the casting process, make them a preferred choice for manufacturers seeking durable and cost-effective solutions. As technology continues to evolve, we can expect to see further improvements in the casting of carbon and alloy steel parts, leading to even greater efficiency and performance.