If you want to maximize the lifespan of your excavato […]

If you want to maximize the lifespan of your excavator, you need to regularly replace the bucket teeth. If they are worn out, the machine will require more fuel and be slower to complete tasks. In addition, dull bucket teeth will cause greater percussive shock during operation, which could damage equipment or undercarriage components. To prolong the life of the bucket teeth, choose a new set of forged or cast teeth.

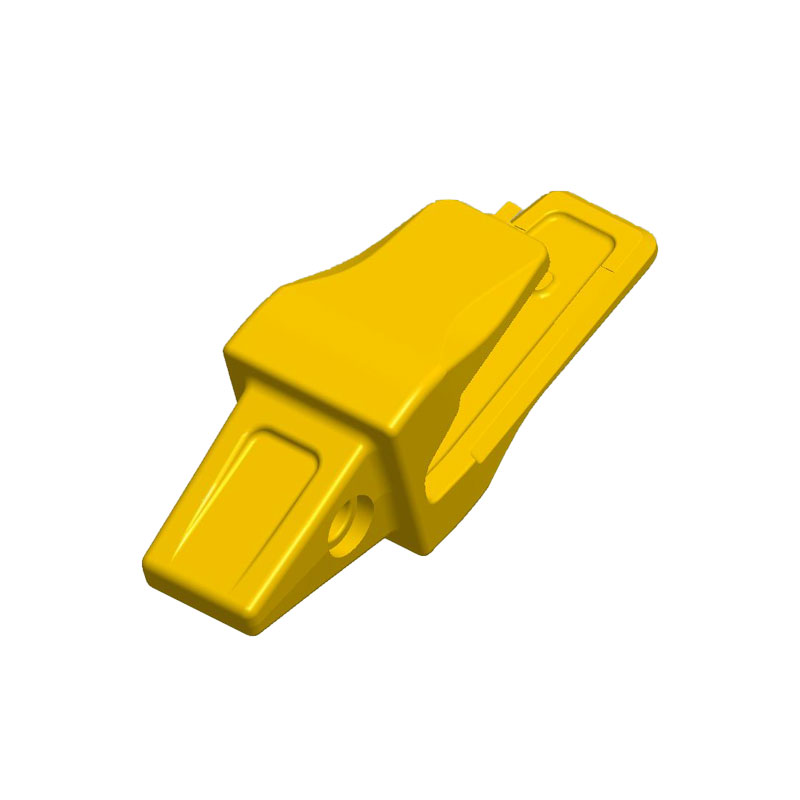

When choosing new bucket teeth, be sure to choose ones that are manufactured from a strong material that can withstand high breakout forces. High manganese steel is widely used for these teeth, but you should also be aware of the wear resistance of the material. Wear resistance of the bucket teeth is directly proportional to their material composition. Moreover, proper teeth-adapter partnerships are important for ensuring optimal bucket life and performance. You can find different types of bucket teeth, each with different hardness and toughness, and choose a set that suits your needs and budget.

The type of bucket teeth you buy for your excavator is very important. Choose the ones with sharp teeth if you need to penetrate harder soil. Sharp teeth will not only protect the machine but also increase productivity. A good excavator bucket tooth is a must-have for any excavator. Make sure you buy one with self-sharpening teeth, as these will help you maintain their efficiency.

The best quality bucket teeth will include the necessary hardware. They should be sold as a complete set, so that you can make the most of your equipment. When purchasing new bucket teeth, make sure to take measurements of your current teeth. A mismatch can lead to inefficiencies or inefficient equipment operation. If you're not sure, check your existing teeth to make sure they fit. If you do not, you'll risk damaging the machine or being unable to use it.

The hardness of the material is important, as it influences the wear characteristics of bucket teeth. A good quality material will withstand heavy use without chipping or fracturing. Its hardness will increase the bucket's overall efficiency and productivity. Regardless of the type of excavator you have, it is important to invest in the right bucket teeth. You won't regret it. These teeth are important to your machine's performance and safety.

When choosing bucket teeth, consider the brand and model of your machine. If your machine is branded with a particular manufacturer, you'll want to check whether it has compatible teeth. Some manufacturers provide bucket teeth for their machines that are only compatible with their own brand. Others may offer a wide variety of options. It is also important to remember that some tooth systems are made for specific machines while others are made for a variety of machines.

Several different materials are available for excavator bucket teeth. One is low alloy steel, which is harder and more resistant to abrasion. Its nickel content increases the strength of the material, while molybdenum improves its hardenability and prevents pitting corrosion. Austempered ductile iron is another material used in bucket teeth. It has been heat-treated to increase its wear and impact resistance.