Casting of alloy steel is an integral part of various i […]

Casting of alloy steel is an integral part of various industries. The process has helped to create a range of high-tech products including watches, cuff links, badges and even gun stocks. The evolution of this process has meant that it is now possible to cast metal of any shape and any size from a variety of different alloys. Alloys such as titanium, alloy steel, aluminium and stainless steel are used extensively in the manufacturing process.

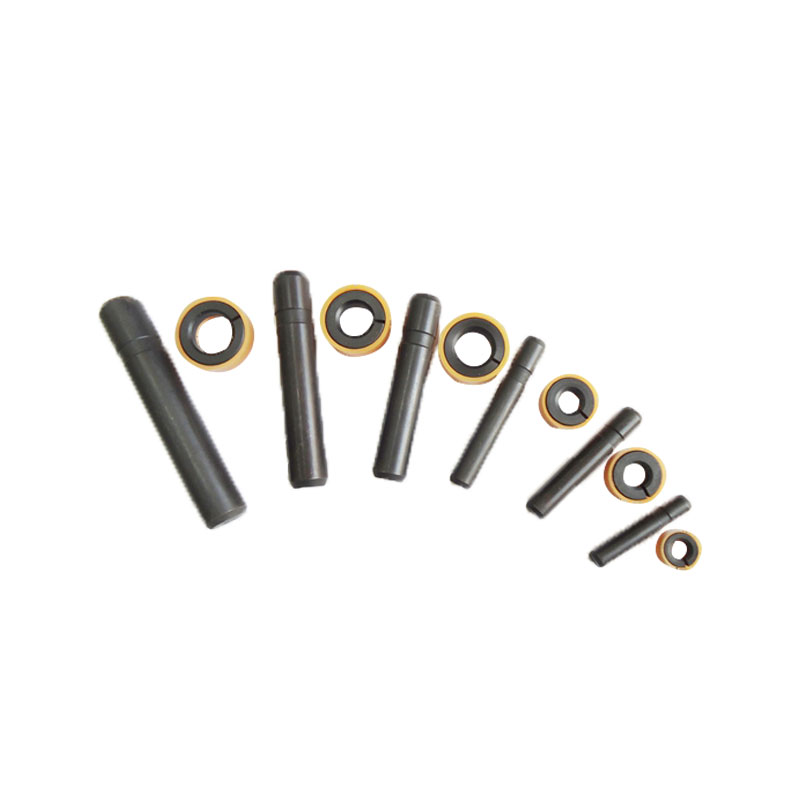

There are many advantages of using alloy steel casting. These parts are strong and are more flexible than traditional steel parts. They also resist corrosion, which is another important benefit when looking for parts. They can be moulded into any shape and in any material, and they can be cast in a variety of sizes. This makes them ideal for companies involved in the manufacturing of accessories and parts for vehicles and other commercial vehicles.

It is not necessary to purchase a new part or design when creating new alloy steel products. Any part already made can be used to create the new part. The whole process of making these parts using this process is called metal casting. It is often the case that parts made by this process can be reused to create other similar parts.

The reason why alloy steel casting is so popular is because of the wide range of options that are available. There are so many different metals that can be used to create parts. In fact, the aerospace industry has recently taken advantage of this technology to create parts such as the tail fin for fighter planes and the main wings of commercial airplanes. In fact, the entire process can be used to create parts that are virtually impossible to make elsewhere.

There are many benefits to using metal casting. One benefit is that it is an environmentally friendly process, as it does not involve any toxic chemicals. Additionally, parts created by this process are stronger than those created by other processes. They are lighter in weight, which makes them easier to transport and to repair when needed.

As you can see, alloy steel casting is a popular way to create metal parts. If you need some parts produced, it is important to ensure that they are produced using this process. This will ensure that you do not put your company at risk. However, before purchasing alloy steel casting services, it is important to make sure that you know exactly what you need. This will ensure that you get exactly what you need for your specific project. Make sure that you choose a company that has experience and expertise in producing these parts, as they will make your project run smoothly and more efficiently.